In the realm of automotive engineering, efficiency, reliability, and performance are paramount. To achieve these goals, engineers and manufacturers are constantly seeking innovative solutions to optimize various components. One such solution is the application of PTFE (Polytetrafluoroethylene) gaskets and seals. PTFE, a remarkable material known for its unique properties, offers significant advantages in the automotive industry.

This article explores the versatility of PTFE gaskets and seals and delves into how they can be effectively applied to enhance the performance and durability of auto parts.

Understanding PTFE

PTFE, a fluoropolymer, possesses exceptional properties that make it an ideal choice for automotive applications. Its non-reactive nature ensures resistance to chemicals, corrosion, and extreme temperatures (-200°C to +260°C). PTFE also exhibits low friction, excellent electrical insulation, and non-stick characteristics. Additionally, it has a low coefficient of thermal expansion and outstanding mechanical strength. These attributes make PTFE gaskets and PTFE seals an invaluable choice for auto parts where reliability, sealing efficiency, and durability are essential.

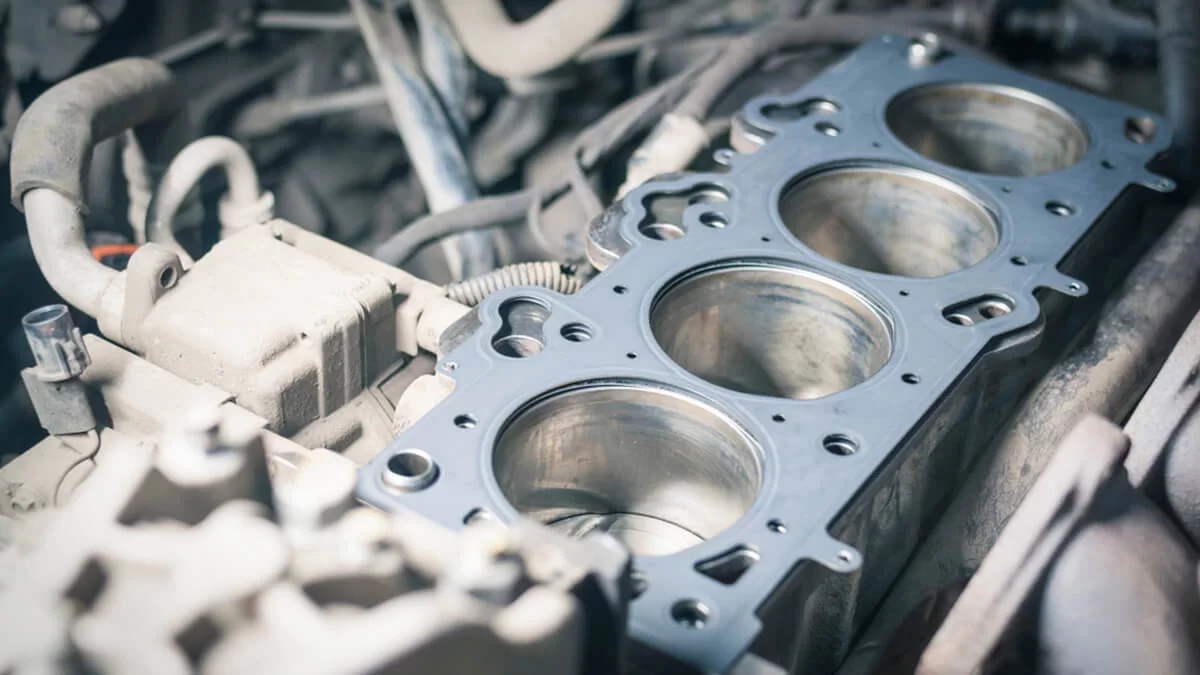

PTFE Gaskets and Seals in Engine Components

The engine is the heart of any vehicle, and maintaining a proper seal is crucial to its performance. PTFE gaskets and seals find extensive application in various engine components. Cylinder head gaskets made from PTFE ensure a reliable seal, preventing leakage and enhancing combustion efficiency. Additionally, PTFE valve stem seals offer excellent lubricity, reducing friction and wear on the valve guides. This contributes to better engine performance, reduced emissions, and improved fuel efficiency.

PTFE Gaskets and Seals in Transmission Systems

Smooth and efficient transmission is essential for a comfortable driving experience. PTFE gaskets and seals play a vital role in ensuring optimal performance in transmission systems. Transmission pan gaskets made from PTFE provide a superior seal, preventing fluid leaks and maintaining consistent hydraulic pressure. PTFE seals used in shafts and bearings minimize friction, leading to reduced power loss and enhanced overall efficiency.

PTFE Gaskets and Seals in Cooling Systems

Maintaining an optimal operating temperature is critical for the longevity of an engine. PTFE gaskets and seals are widely utilized in cooling systems to prevent coolant leakage and ensure efficient heat transfer. PTFE radiator gaskets offer excellent resistance to chemicals and temperature variations, guaranteeing a reliable seal. Moreover, PTFE seals in water pumps and thermostats reduce friction and wear, contributing to extended component life and improved cooling performance.

PTFE Gaskets and Seals in Fuel Systems

Fuel systems require reliable seals to prevent leakage and maintain proper fuel flow. PTFE gaskets and seals exhibit exceptional chemical resistance, making them suitable for use in fuel systems. PTFE seals in fuel injectors ensure proper fuel atomization, resulting in improved combustion and reduced emissions. PTFE gaskets used in fuel pumps provide a secure seal, preventing fuel leaks and maintaining system integrity.

Conclusion

In the quest for automotive performance, PTFE gaskets and seals have emerged as indispensable components. From engine components to transmission systems, cooling systems to fuel systems, PTFE gaskets and seals play a pivotal role in enhancing performance, durability, and reliability. As the automotive industry continues to evolve, the versatile application of PTFE gaskets and seals is poised to contribute significantly to the development of more efficient, sustainable, and high-performing vehicles.